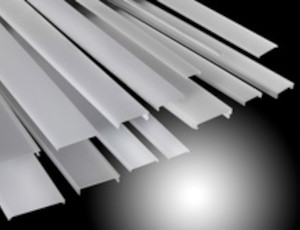

Plastic Parts

Plastic Injection & Extrusion

We offer plastic extrusion and plastic injection manufacturing services for Elastomer, Thermoplastic and Thermostat material from 18 to 3000 tons of pressure, as well as:

- Small machines for high precision parts

- Large machines for parts up to 25kg

- 2-components extrusion with 120-200 tons pressure

- High-speed with nitrogen gas for thin-wall molds

Machining

- Manual/Auto Silk Screening

- CNC

- Tampo or pad printing

- Wire-cut

- Cold/hot stick

- Ultrasonic

- Wet paint (spray paint)

- Assembly

Design & Drawing Verification

Our design input during the design stage promotes the manufacturability of the product and leads to a more robust design.

We use sophisticated CAD-CAM technology to ensure optimal execution of drawings with tolerances of up to 0.02mm.

Threesome Technical Collaboration

This collaborative approach between the customer, us and the tool makers improves engineering productivity and time-to-market because it avoids expensive, time-consuming downstream changes.